Flex Pipes

FLEXPIPE Polybutene – 1

Hot & Cold Plumbing & Heating Systems

FLEXPIPE is another innovative product of Bahrain Pipes Factory for polybutene-1 hot & cold plumbing and heating system. Polybutene is made of high quality raw material using product specified extrusion parameters and close supervision during the manufacturing process. Basell Polyolefins, Netherlands and Nueva Terrain, Spain have provided technical support to ensure the consistence quality of FLEXPIPE.

The polybutene-1 product is also certified by a third party certification firm in Germany. The flexible resins and linear polyolefins provide uniquely combined properties which make FLEXPIPE technically superior to other similar products. Excellent resistance to creep at room and elevated temperatures, high pressure loading at high temperature, high impact strength, puncture resistance and exceptional resistance to environmentally stressed cracks have been estimated to provide a period of more than 40 years durability.

Excellent electrical insulation characteristics, non-corrosion, resistance to most chemicals including salt water, low stress build-up upon temperature changes, low thermal conductivity and light weight are the beneficial factors of FLEXPIPE. Its exceptional flexibility and light weight feature allows it be used for multi-directional and longer pipe run installation reducing the number of fittings.

The non-metallic surface of FLEXPIPE is not affected by the build-up of scale. FLEXPIPE is not just a world class product but an investment in plumbing.

By manufacturing polybutene pipes, Bahrain Pipes Factory joins the elite team of international pipe manufacturers and is the only manufacturer of polybutene-1 in the Middle East.

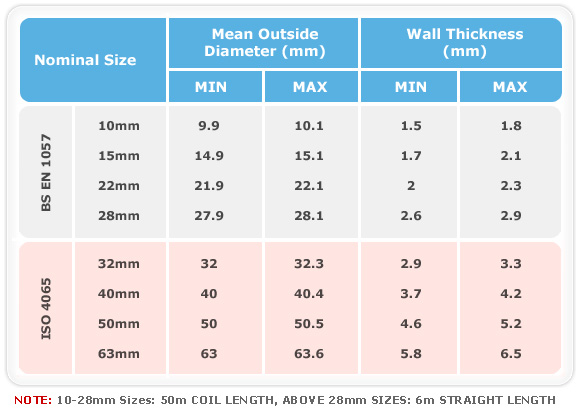

♦ FLEX PIPE DIMENSIONS : BS7291-2:2000

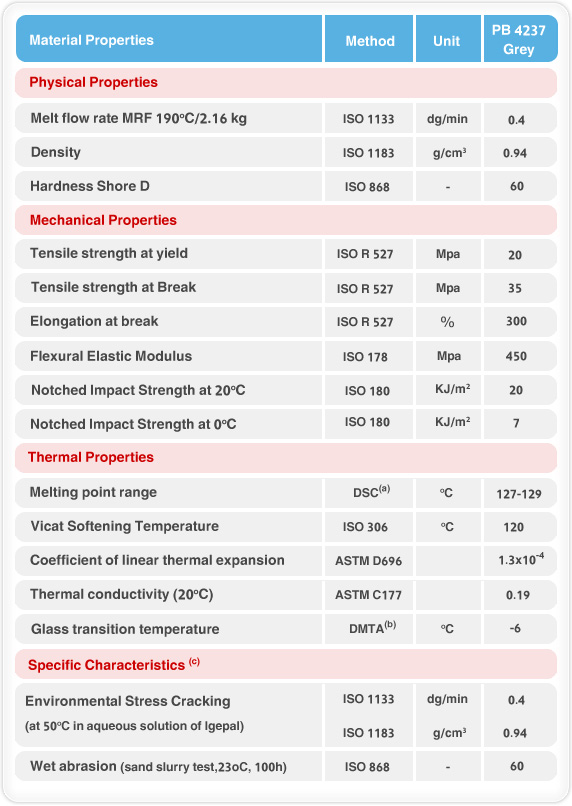

♦ TYPICAL PROPERTIES

FLEXPIPE resins are flexible, linear polyolefins that offer a unique combination of properties. They are produced from 1-butene yielding polybutylene – homopolymer having high molecular mass. Among its important advantages are : excellent resistance to creep at room and elevated temperatures, very good impact toughness (high impact resistance) and exceptional resistances to environmental stress cracking. From polybutylene – (PB-1) resins having these characteristics, FLEXPIPE is born.

Additional important benefits of FLEXPIPE include excellent electrical insulation characteristics, no corrosion, light weight, resistance to most chemicals (including slat water), low stress build-up upon temperature changes and low thermal conductivity resulting in moderate pipe surface temperatures at hot water application (no skin burn).

♦ APPLICATION

Among the most valuable applications of FLEXPIPE are pipe pluming systems for residential and industrial use. Because of its superior properties FLEXPIPE technically out-performs all other pipe alternatives. Perfect for portable water FLEXPIPE can sustain high temperature and stress while maintaining lower wall thickness, thereby saving pipe weight and more internal diameter enabling maximum water flow through the piping network.

♦ FLEXIBILITY COMPARISION HIGH FLEXIBILITY

Polybutylene – Polymer (PB-1), where FLEXPIPE is made of, has the lowest flexural modulus and allows for the thinnest pipe wall of all polymer resins used for domestic hot and cold water plumbing systems. Because of their outstanding flexibility longer pipe runs can be used to accommodate directional changes.

♦ TENSILE STRENGTH / PRESSURE PERFORMACE

Pipes made from PB-1 have low rigidity and very high tensile strength at higher temperature resulting in high pressure resistance and higher design stress than other plastic pipe. this results in proved flexibility and lower wall thickness leading to lighter weight of pipe and larger bore diameter that continuously provides abundant water flow.

♦ PERFORMANCE COMPARISON CREEP RESISTANCE

FLEXPIPE has excellent creep resistance that cannot be attained from any other polymer used for plumbing purposes today. Because of excellent creep resistance characteristics FLEXPIPE maintains its unique pressure performance and have been estimated to have long service life of over 50 years.

♦ CREEP BEHAVIOR

FLEXPIPE manufactured from PB-1 resin has an exceptional combination of properties that makes it technically superior. It is the preferred choice for behind the wall plumbing system applications. The extended service life and durability of FLEXPIPE must not be under-estimated.

Performance Benefits of FLEXPIPE Quick and Easy Installation

The flexibility of polybutylene – pipes also provides quickest and easiest installation in confined spaces. FLEXPIPE is lightweight and can be used for longer pipe runs and multi-directional installation reducing the number of fittings.

♦ CORROSION FREE

FLEXPIPE does not corrode like traditional pipe made of copper or iron. It does not react with ionic species commonly found if water and environment and will not leach thus preventing penetration of harmful and dangerous substances into potable water.

♦ NO SCALE BUILD-UP

commonly and major problem encountered particularly in hard water area in the build-up of water scale on internal walls of metal pipe. Water scale gradually reduces the internal bore thereby restricting the flow of water out of the faucet. Being non-metallic, FLEXPIPE is not affected by scale build-up making it an ideal choice for water pipeline systems especially for hot water lines.

♦ SILENT OPERATION

Research shows a strong public demand of noiseless plumbing operation. FELXPIPE plumbing systems greatly reduce noisy operation and water hammering commonly experienced with hard metal pipe systems with quick acting valves. FLEXPIPE is an investment in plumbing highly suitable for consumer needs.

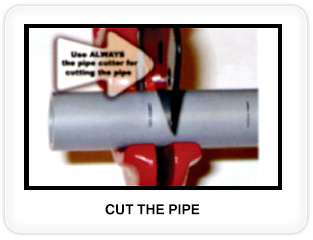

ASSEMBLY METHOD

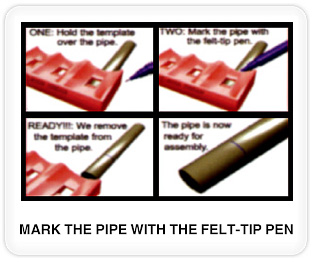

FLEXPIPE is marked to indicate suitable cutting positions to ensure correct depth of insertion into fittings which contain a molded stop limiting the maximum depth of insertion of the pipe.

01. Tools – Flet-tip pen Template Lubricating Silicone pipe Cutter.

02. Cut the pipe perpendicularly pressing with a circular movement ensuring that the end cut does not have any swarf.

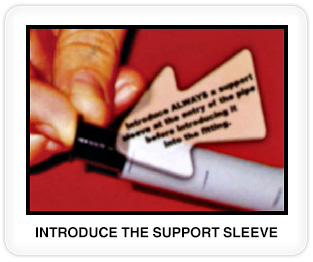

03. Introduce support sleeve inside the pipe, otherwise the pipe could come out of fitting.

04. Mark with felt-tip pen the penetration distance using the template.

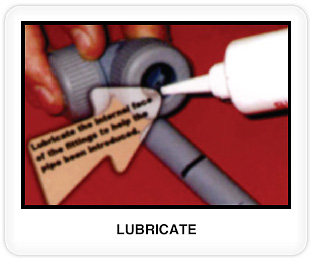

05. Lubricate internal wall of the fitting and external of the pipe with lubricating silicone. This will make assembly easier.

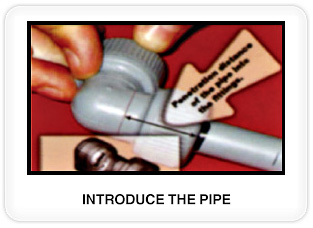

06. Push the end of FLEXPIPE firmly into the fitting until the stop. The joint is correctly done if the depth of insertion is in line with the retaining nut.

PIPE PERFORMANCE

♦ LONG-TERM BURST PERFORMANCE

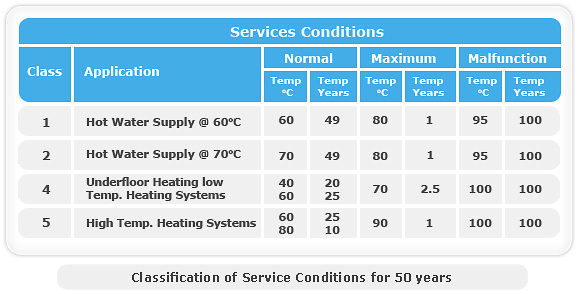

The resistance of pipes to deformation and burst is determined by testing to international / national standards. The test results are then used to calculate the maximum permitted hoop stress for hot water transportation according to defined set conditions referred to as temperature classes. These temperature classes are compiled to reflect the likely cross-section of service conditions for a 50-year period for a range of different heating and water supply applications.

♦ BENEFITS AND ADVANTAGES OF FLEX PIPE

- Polybutene-1 pipes provide a completely corrosion-free drinking water and heating pipe system. Freedom from corrosion means there is no contamination of the water at the tap by products of corrosion.

- Freedom from scale build-up and encrustation in hard water supply areas is guaranteed. Smooth internal pipe surfaces combined with inert chemical properties leads to the complete elimination of calcium carbonate deposition, thus ensuring long-term efficiency in water heating and circulation.

- Resistance to freezing temperatures – the flexibility and elastic properties of Polybutene-1 ensure that pipes will not burst or be damaged by freeze-ups during cold weather.

- The low thermal conductivity of Polybutene-1 means that hot water pipes are cooler to the touch than conventional metal pipes and the incidence of condensation on the pipes is reduced, providing a safer system.

- Due to low thermal conductivity, combined with the fact that thermal expansion is accommodated by the inherent flexibility of the material, Polybutene-1 piping systems are quiet with no water hammer and minimal system creaking.

- Polybutene-1 piping systems are electrically non-conductive, providing a safer with minimum earthing requirements.

- Polybutene-1 pipes can be installed as a conduit ‘pipe in pipe’ system through concrete floors and walls. Such a system provides low maintenance security. If there is ever an unexpected need to replace such an installed pipe, this can quickly and easily be accomplished by disconnecting the ends of the pipe, connecting a replacement length to one and pulling the new pipe through the conduit into position. The flexibility of Polybutene-1 pipe makes this an easy task.