HDPE pipes

Water is of vital importance: Without water no life would exist and our planet would be a huge desert. Plants, animals and humans are composed of 50 – 80 % water, from polluted water or water scarcity however, they suffer, fall ill or even die. Therefore, our common future is endangered when water is not available in sufficient amount and quality.

Water is a heritage of nature and it belongs to all living beings. The right of access to sufficient and clean water is a universal law and it is therefore anchored in important international treaties. The uneven distribution of rain and water on Earth leads to water scarcity in many regions. Already today 1 billion people (20 % of the world population) have no secure access to clean drinking water and 2 billion people do not dispose of access to sanitary installations. Thousands of children die every year due to polluted water. Moreover global climate change will intensify the water crisis. All these facts force the world population to react in order to rescue our home planet.

To improve this situation and find solutions a lot of governmental bodies, engineering and construction companies as well as pipe manufacturers have focused in this world threatening issue. However, for years tremendous difficulties were observed when selecting the material of construction for infrastructure systems, which should be suitable to provide anticipated permanent solutions.

Over the last decades the inherent weaknesses of concrete, clay, ductile, PVC and steel caused tremendous problems in existing sewer pipe systems, as they tend to be brittle or are too sensitive to aggressive chemicals and soil conditions. Failures had become a common occurrence worldwide in sewer and other large-diameterpipe applications. In addition they have a unprofitable relation between cost and benefit.

So Krah derived benefit from the fact that the processing of polyolifines is very easy and the plastic materials provide superior properties against adverse effects of the ambient and the chemicals.

In addition to the permanent solution that lasts through generations, Krah piping system is able to provide everlasting and economic solutions in wide-ranging fields of applications as for example drain, stormdrain and sewer systems as well as sea outfall, manholes and reservoirs.

In order to meet the requirements of the infrastructure systems, Krah has developed the most robust and advantageous large-bore-pipe systems of which all features are described in detail in this brochure.

Material

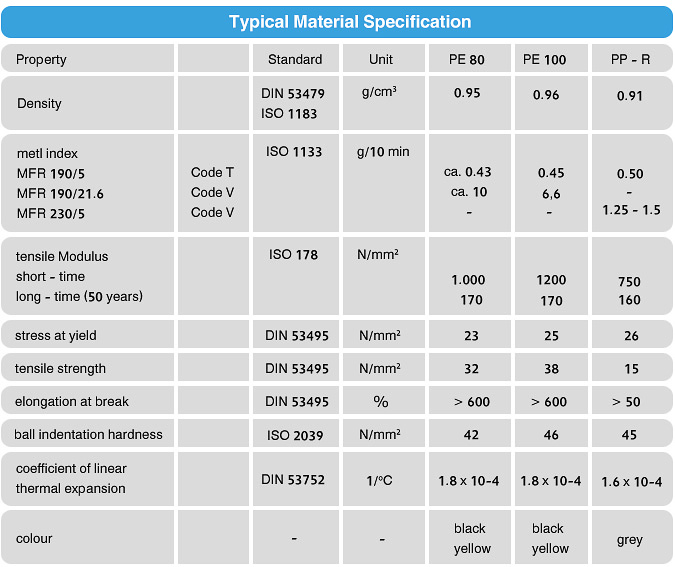

Polyethylene (PE63, PE80 and PE100) and polypropylene are thermoplastics with excellent properties for the application of water and sewer, as well as for the fabrication of containers for liquids and solid materials. The environmental friendly polyethylene and polypropylene are resistant to many chemicals and very suitable for conveying and storing various liquids.

Krah pipes can be produced of the following thermoplastic materials:

- High density polyethylene(PE80 and PE100)

- Polypropylene-random (PP-R)

- Polypropylene-homo (PP-H)

- Polypropylene-none-flamable (PP-S)

These materials feature below mentioned properties. Other materials can be used after prior acceptance of the producer and a third party for quality control. However, the processed material should have the below listed specification.

Since the latest developments, high stiff polypropylene can be used, if you are interested ask for further information and data sheets.

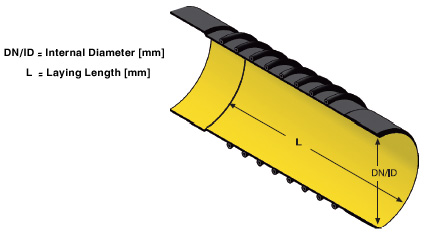

Pipe Diameter

Krah pipes can be produced stepless at intervals of 100 mm with internal diameters (ID) from DN 300 mm to DN 4000 mm.

The nominal diameters (DN) coincidents with the internal diameter (ID) of the pipe, because in case of any change in the design of the pipe, the wall thickness can be increased or reduced while the internal diameter remains the same. This ensures that the designated hydraulic capacity for the installation is maintained.

Pipe length

The standard laying length (L) of the Krah pipes is six meters, because in this way they are easy to handle, store and transport.

In addition it is possible to produce continuously any length between one and six meters. The longer a pipe is the fewer joints are necessary and this is advantageous for the installation of the pipe. Moreover it is possible to deliver the pipes already jointed, whereby the installation time on site can be reduced signifcantly. Lengths up to 18 m consisting of 3 pipe sections are common.

Wall thicknesses

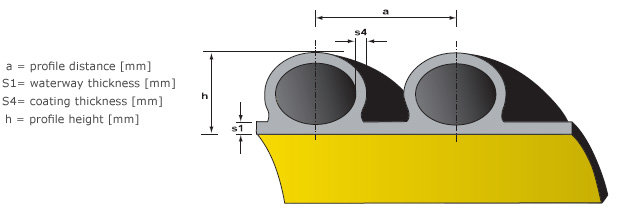

Both profiled and solid wall pipes with wall thicknesses up to 300mm can be produced.

The quality of the pipe is highly depending on the quality of the waterway wall, therefore all Krah pipes are usually produced with a minimum waterway wall of 4mm.

Profiled pipe wall

The great advantage of this development is that a profiled pipe has a very low weight, but at the same time can be used for high load applications. A lot less material is needed to produce a pipe with the same statical properties than a solid wall pipe, which means significant savings in material costs.

The supportable static load is determined for every profile geometry by the factors elastic modulus [N/mm2] of the respective material and the moment of inertia of the profile geometry [mm4/mm] referring to the pipe diameter. The result is called ring stiffness. By using a profile design pipe, the weight can be reduced up to 65% compared to a solid wall pipe with the same ring stiffness. Krah pipes offer the best security and durability. The wall thicknesses of our pipes can be adapted in small steps to the respective load.

Internal pressure

The Krah pipe system can withstand low working pressure up to 3 bar, depending on the thickness of the waterway wall (s1). Equivalent to DIN 8074 the hoop stress formula can be used with s1 as the minimum wall thickness.

Co-extrusion

If requested all pipes can be delivered either with a bright, inspection friendly or an electro-conductive inner surface made by the co-extrusion process.

The co-extrusion ensures an inspection friendly, bright inner surface and at the same time a long term UV-resistant outer surface (for example for the storage of pipes outside for a long time).

Norms and standards

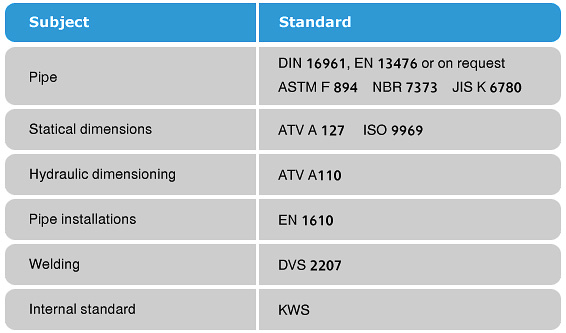

The Krah piping system is designed to meet the requirements of present applicable international norms and standards.

The Krah pipe corresponds to the following international standards: